Installation Procedure for Water Level Controller:

Semi Automatic Model Level Controller for (220V AC) Single Phase Pumpset.

Installation of our water level controller system is not a major task and we have made the system in such a way that it is possible to install the system yourself with minimum electrical knowledge or with the help of a simple electrician. The task of installation comprises of two parts, the Power Connection and the Sensing Connection.

The Power Connection is the connection between the Water Level Controller and your existing Starter or the Switch with which you are presently operating the Pumpset. Sensing Connection includes the cabling of sensing wire, i.e., any good quality 2 core wire from the Water Level Controller to the Overhead Tank (OH Tank). After cabling, making the level sensing arrangement in the water tanks and Sensing connection of the sensing cable to the Water Level Controller.

Tools required for Installation:

- 4 Pair CAT 5e Communication cable as per requirement. Take a rough estimate of cable length from the pump control switch location to the OH Tank and again from the pump control switch to the UG Sump (for Bore well, cable is required only for the OH tank).

- Multi strand 1.5 Sq.mm. Copper Power cable of about 2 to 6 meters as per requirement for power connection.

- Line Tester.

- Insulation Tape, necessary screws and wooden gattas pieces for mounting controller unit on the wall.

- Cutting Pliers or Nose Pliers.

- Simple Hammer-Jumper set or Drill Gun to mount the Level Controller to wall or to wooden board.

Sensing Cable Connection to Water Level Controller.

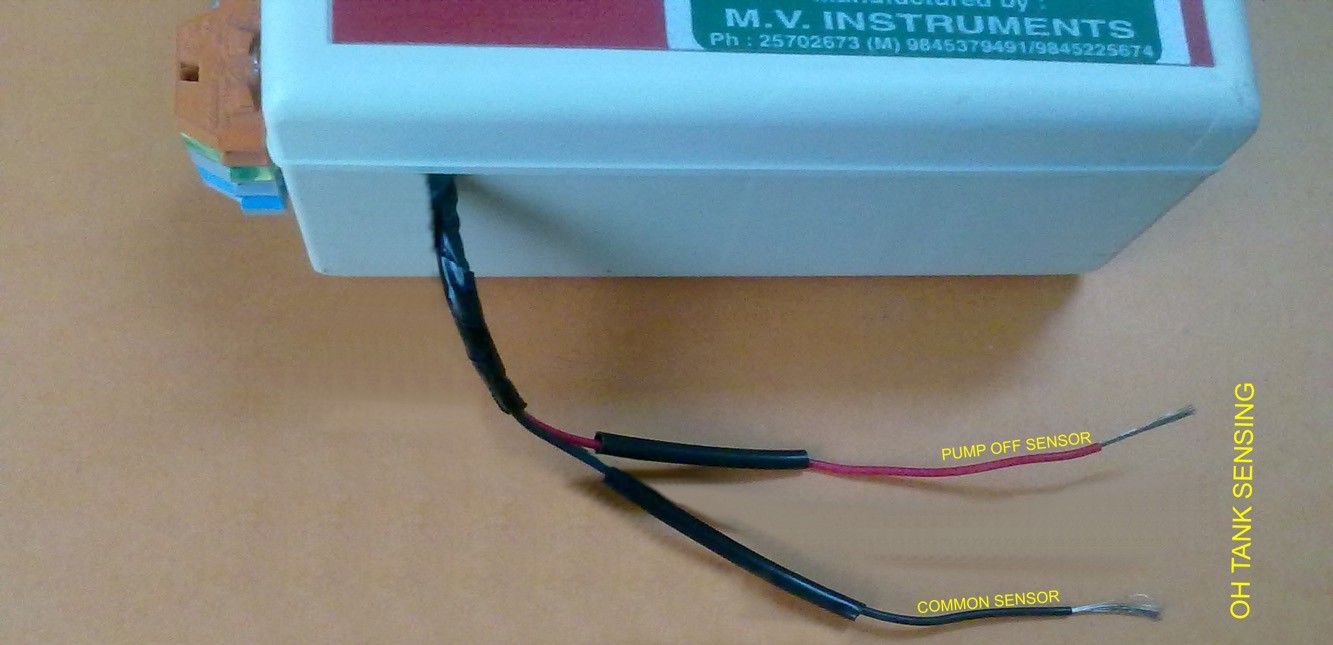

STEP 1. The sensing wires comprises of a pair of coloured wires in the bottom of the unit for upper Tank or OH Tank.

STEP 2. Do complete sensing wiring from Water Level Controller to Overhead Tank and leave about 1 Meter of wire extra in the tanks.

STEP 3. To connect the sensing wires of OH Tank to the Water Level Controller unit, simply twist the two sensing wires to the two wires of Water Level Controller unit. Slide the PVC sleeve provided over the twisted joint completely. The advantage of having loose sensing wire over the sensing terminal block is that, loose contacts are avoided and testing of the controller functions can be done easily by shorting the sensing wires in the controller itself directly.

Sensor Probes Connections and Sensors Level setting in Overhead Tank and Underground Sump.

Tank Sensing Procedure:

STEP 1. Do the 2 core cabling from the level controller to overhead tank and leave about 1.5 extra cable near overhead tank.

STEP 2. To give the Sensing connection in the Overhead Tank, initially decide the levels at which the pump has to switch OFF. As usual procedure, OFF Level can be 2 to 3 inches less than 100% capacity of Tank (Overflow Level).

STEP 3. Take an electrical PVC pipe of 3/4th inch or 1 inch which is commonly available. Cut the pipe about 2 feet so that pipe can be hanged vertically inside the tank.

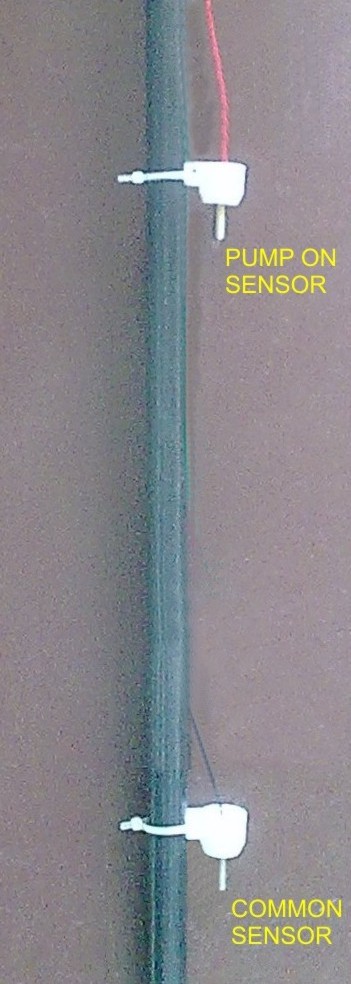

STEP 4. The Level Controller comes with Plastic Molded SS Sensor Probes, with 1.5 Met. length of wire, which are suitable to fix to the PVC Pipe with the help of Cable Ties (which will be supplied).

STEP 5. Insert the Cable Tie to the sensor probes and fix it to the PVC Pipe as shown in the Photo at required Common and OFF levels to the PVC pipe.

STEP 6. Terminate the sensing cable which is wired from Level Controller to the OH Tank and the wires of the Sensing Probes at the Two way Terminal Block outside the OH Tank. Secure the Terminal Block to nearby water pipe.

STEP 4. Fix the sensing wires to the top of the PVC pipe with insulation tape with the regular insulation tape.

STEP 5. Make the loop of the sensing wire, to hang the sensing arrangement to the top portion of the tank with the help of a hook or nail.

STEP 6. The sensing arrangement should be away from the wall of the tank and also should be away from the water falling into the tank.

STEP 7. Sleeve the wire and connect them to the Two way Terminal Block outside the OH Tank. Secure the Terminal Block to nearby water pipe. Connect the other wire end of SS sensor probe to the terminal block in the following order: -

- Set the level of Common sensor (Black wire pair) at about one feet below the full level of the Tank.

- Set the level of Pump OFF sensor (Red wire pair) at the Full level of the Tank.

Important: The Sensing wire from the unit to OH Tank should be a one-piece wire and there should be absolutely no joints in these Sensing wires and these wires should not be damaged in any way. Unit will not operate correctly in these cases. Continuity of wire should be checked before wire is laid. This sensing wire can be put inside PVC pipe throughout for extra protection.

Power Connection from the (220V AC) Single Phase Starter / MCB / DP Switch to the Water Level Controller.

STEP 1. Isolate the Main Power Supply before the Power Connection Procedure and remove the top cover of Starter or Switch.

STEP 2. Identify Phase & Neutral wire in the Starter with "LINE TESTER" after switching ON the power supply.

STEP 3. Now switch OFF the Mains and remove the output terminals of the starter or DP switch, i.e. Phase and Neutral terminals.

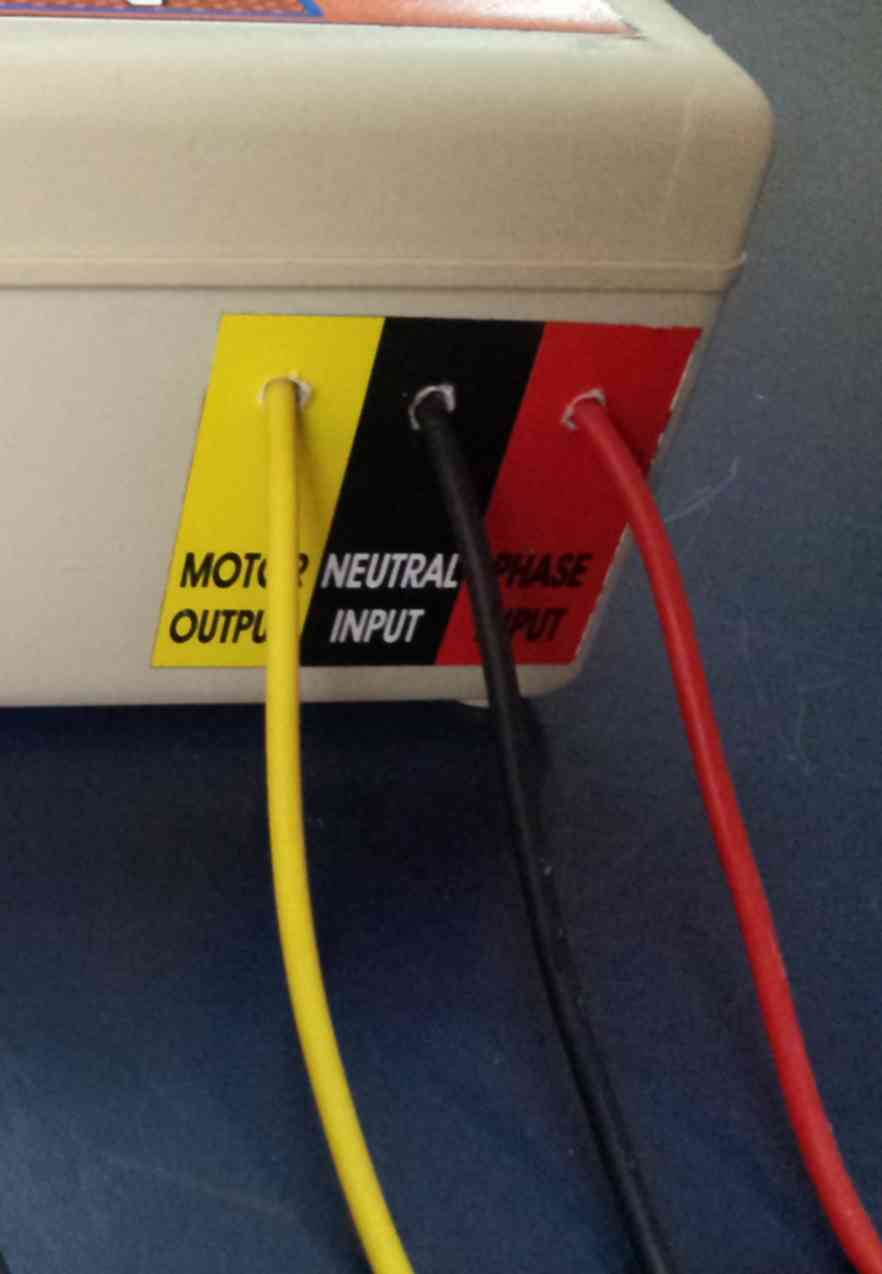

STEP 4. Identify the Power Terminal Block with sticker of connection details on the bottom of Water Level Controller.

STEP 5. Connect Phase and Neutral Output terminals of starter to the power input terminals "PHASE I/P" and "NUTRL I/P" of Water Level Controller as shown in diagram. To give connection, just press the terminal from top and insert the wire from bottom.

STEP 6. Connect the removed motor wires to Output Terminal "PHASE O/P" and "NUTRL O/P" of Water Level Controller as shown in diagram. To give connection, just press the terminal from top and insert the wire from bottom.

STEP 7. Now the power connection is completed.

STEP 8. Put the Auto/Manual Switch of Level Controller to Manual Mode, switch ON the Mains to Confirm that the motor in working in Manual Mode.

STEP 9. Now put the Auto/Manual Switch of Level Controller to Auto Mode. "Power ON" LED should glow. Some times if the water level is less in OH tank, Pump may switch ON.

Testing of Complete Automatic System.

Keep the delay wires(thin wires) open before testing procedure. Now switch ON the level controller in Automatic Mode.

OH Tank testing procedure:

STEP 1. Then start testing the OH Tank function. This can be done by immersing and lifting of the sensor arrangement in the OH Tank water.

STEP 2. In OH Tank, lift Pump OFF sensor above water level. Now push the Trigger Button to start the pumpset.

STEP 3. Now immerse Pump OFF sensor also inside the water, now pump should switch OFF immediately.

STEP 4. Now lift only Pump OFF sensor from the water, Pump should remain OFF.

STEP 5. Repeat the steps from STEP 2 to STEP 4 for four to five times to ensure the correct operations.

STEP 6. Now OH Tank testing is completed.