The Product Range of Our Company Previous Model Next Model

The Water Leakage Detection System:

Water leakage is one of the reasons for any Technical Failures of Operations in many Technical Infrastructures where human presence is limited, like in Server Rooms, UPS & Battery Rooms, Electrical Panel Rooms, Data Centers, DG Rooms, and also in Storage Areas of valuable commodities :

Why Water Leak Detection is Crucial in Technical Infrastructure?

- Equipment Damage: Water can cause short circuits, corrosion, and permanent damage to equipment, storage devices, network gear, and power distribution units (PDUs).

- Downtime: Equipment failure leads to service interruptions, impacting business operations significantly.

- Data Loss: Damage to storage media and servers can result in irreversible Data Loss and Down Time.

- Safety Hazards: Water combined with electricity creates serious electrocution risks for personnel.

- Hidden Leaks: Raised floors, common in server rooms, can hide leaks until significant water has accumulated, making early detection vital.

- Sources of Leaks: Potential sources include:

- Air Conditioning (CRAC/CRAH) units (condensation, drain pans, chilled water lines).

- Plumbing pipes running overhead or nearby.

- Roof leaks due to Rain water & Accidental overflow or spills.

- Sprinkler system malfunctions of Fire Hydrant.

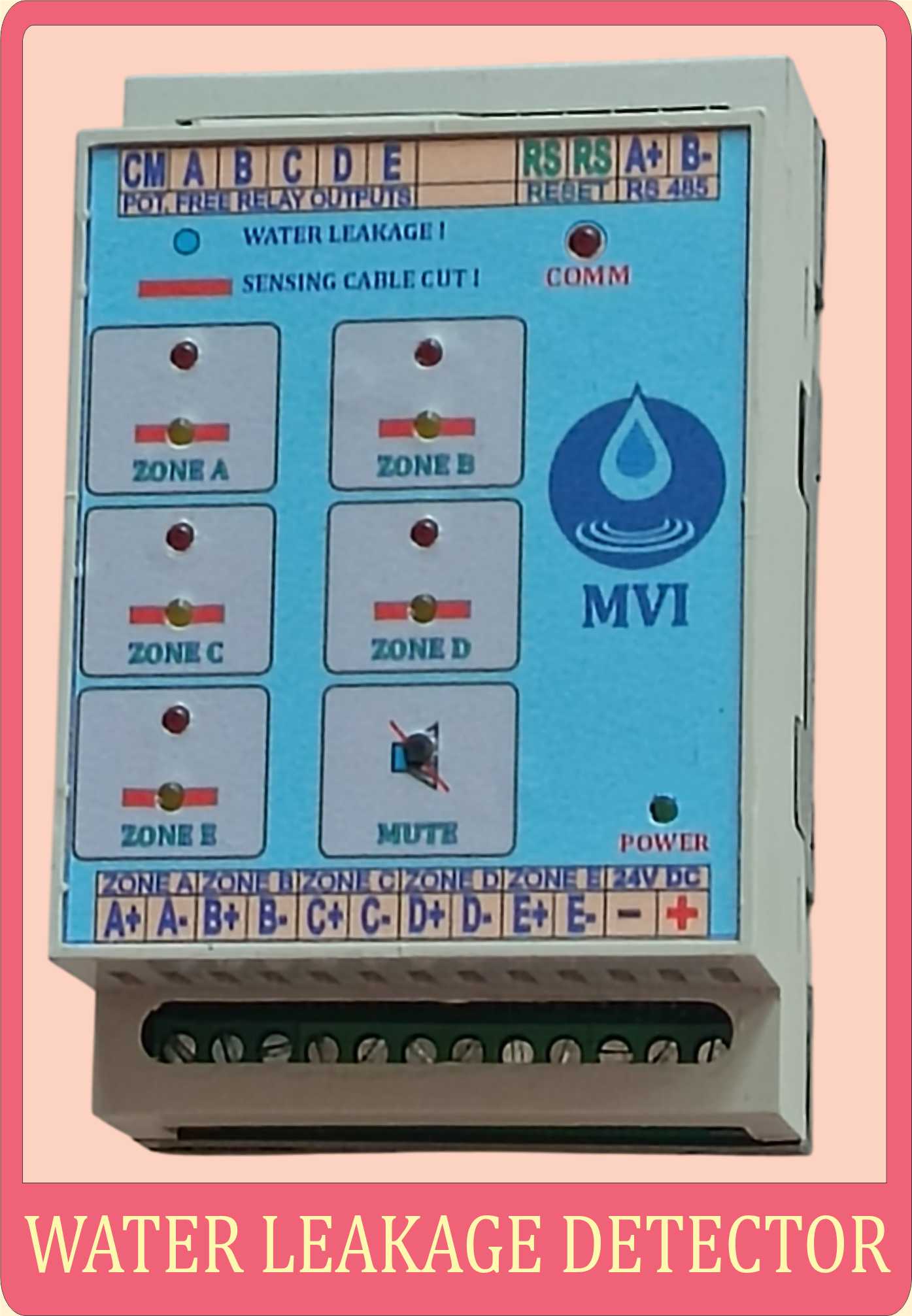

The WLD 5ZX Detector Model Description:

The WLD 5ZX model is a microcontroller design SMD based embedded system. It is an advanced Serial Communication and IoT based Industrial Grade Product. The system will be mounted in either Server room or Electrical Panel room and will have 5 independent sensing cables running to all probable 5 locations where leakage have to be monitored. The water leakage detection system typically comprises of following sections:

- Water Leak Sensors: Spot Detectors or Cable Sensors mounted on the room floor and connected to Main Panel.

- Sensing and Indication Panel: The central unit that receives signals from the sensors, processes them, and initiates alarm & annunciation.

- Alarm/Annunciation System:

- Local: Audible Local Buzzer and visual LED Indication in the front panel mounted in the server room

- Remote: External sirens driven through potential free relay contacts, Integration with monitoring systems via protocols like SNMP (Simple Network Management Protocol), Modbus. This allows alerts to be sent via integrated Serial Communication into Building Management Systems (BMS), Network Management Systems (NMS), or Data Center Infrastructure Management (DCIM) software, IoT Based Mobile Notification Applications (MNA)

- Power Supply: AC mains powered with DC 24V Adaptor with a battery backup to ensure operation during power outages.

Types of Water Leak Detection Sensing Systems:

There are two primary types of sensors used in server rooms. Depending upon the size and layout of the server rooms, the choice of the sensors and their quantity and location can be planned:

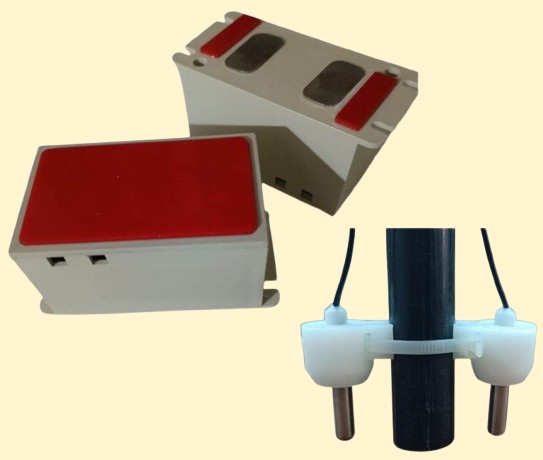

- Spot Detectors:

- How they work: These are small, individual sensors placed in specific locations deemed high-risk (e.g., under AC units, near water entry points, low points on the floor). They typically have SS probes place 1mm above ground level that trigger an alarm when water bridges the contacts.

- Pros: Relatively inexpensive per unit, easy to place. Any number of sensors can be placed and can be connected in parallel to cover wide range of room. Easy to maintain during cleaning of Room.

- Cons: Only detect leaks at the exact location where they are placed. A leak occurring even a short distance away might be missed until water spreads significantly to the sensor location.

- Cable Sensing (Leak Detection Cables):

- How they work: These are flexible cables laid out over and clipped to the floor of larger areas, often around the perimeter of the room, under raised floors in a grid pattern, or specifically around critical equipment or potential leak sources like AC units. The external surface of the cable detects the presence of water anywhere along its length. When water touches the cable, it senses the leak and sends the signal to the system.

- Pros: Provide wide-area coverage, detecting leaks precisely where they occur along the cable's path. Ideal for under raised floors and comprehensive monitoring. Some systems can even pinpoint the leak's location along the cable.

- Cons: Can be more expensive initially than spot detectors, especially for large installations. Installation under raised floors requires more planning.

The Salient Features of the Product:

- The system checks for the water leakage in the localized significant locations in the Server Room and alerts with local alarm and potential free contacts along with remote communications.

- The system will sense the water leakage in floor area of the server room below the false floor with 5 Independent sensing Zones. This makes it easier to locate the fault quickly and attend the same.

- The sensing signal is 100Hz AC signal with analog voltage level sensing for highly accurate and reliable maintenance free sensing backed with decades of technical knowledge. The system can sense wetness on the sensor as well as any damage of the sensing cable making it either short circuited or open circuited state.

- The system indicates the status of the leakage in the front panel of the unit with LED indication and has a RS485 protocol to indicate the same through serial communication.

- The communication protocol can be configured for required Baud Rates, Parity Bits, Slave IDs, Addresses and remote signals will be available for water leakage in 5 zones as well as cable fault in 5 zones.

- In case of leakage in any area, the system starts blinking that particular Zone LED light and will start a buzzer for audible indication.

- The system has Acknowledge Button on front panel to Mute the siren before attending to the fault. This silences the siren and buzzer but the indication will remain ON till the fault is cleared. There is a provision for Remote Mute button.

- The system can be easily expanded to have multiple sensors per Zone or have longer cables if the server room requires to have extensive sensing areas.

- The system also has a potential free relay with Normally Open contacts which Closes In case of leakage hazard for every zone which can be used for external siren driving or for electrical logic circuits.

- The system comes in DIN Rail mounting and can be mounted in any suitable panel.

- The system has a unique facility of sensing for any damage in the sensor cable, i.e. if the sensing cable which runs from the annunciation unit to the sensor location, gets cut anywhere in between, the unit senses that fault and alerts the operator with alarm and LED indication that the cable is cut and also will indicate the zone where the fault has occurred. This will make the system functionality a fool proof arrangement.

- The system operates at 24V DC power supply. The system can be powered with DC Power Adopter of 24V DC with backup of 24V DC Battery in circuit. The system works flawlessly even up to 12V DC battery voltage drop during battery backup. The DC Power Terminals are Reverse Polarity Protected.

- The system is housed in ABS enclosure and has industrial grade internally mounted terminal connectors.

- The system can be easily integrated with existing monitoring infrastructure (BMS, NMS, DCIM) if the requirement is crucial. The system has reliable alerting, good integration capabilities, and ideally, location pinpointing features for faster incident response.

![]() Download e-catalouge in pdf format.

Download e-catalouge in pdf format.

To understand more or for any specific requirements or for any clarifications, Please mail us or call us with details for custom support.